In summary, while both peripheral pumps and centrifugal pumps are useful for pumping fluids, they have different impeller designs, performance characteristics, construction, and energy efficiency, and are suited to different applications. Choosing the right type of pump depends on the specific requirements of the application, including flow rate, pressure, head, and efficiency.

Centrifugal pumps have a multi-stage impeller with curved blades that rotate within a volute casing, generating pressure and flow by centrifugal force. This impeller design allows the pump to handle high flow rates at low to medium pressures. Centrifugal pumps are commonly used for industrial applications such as water supply, sewage treatment, and chemical processing.

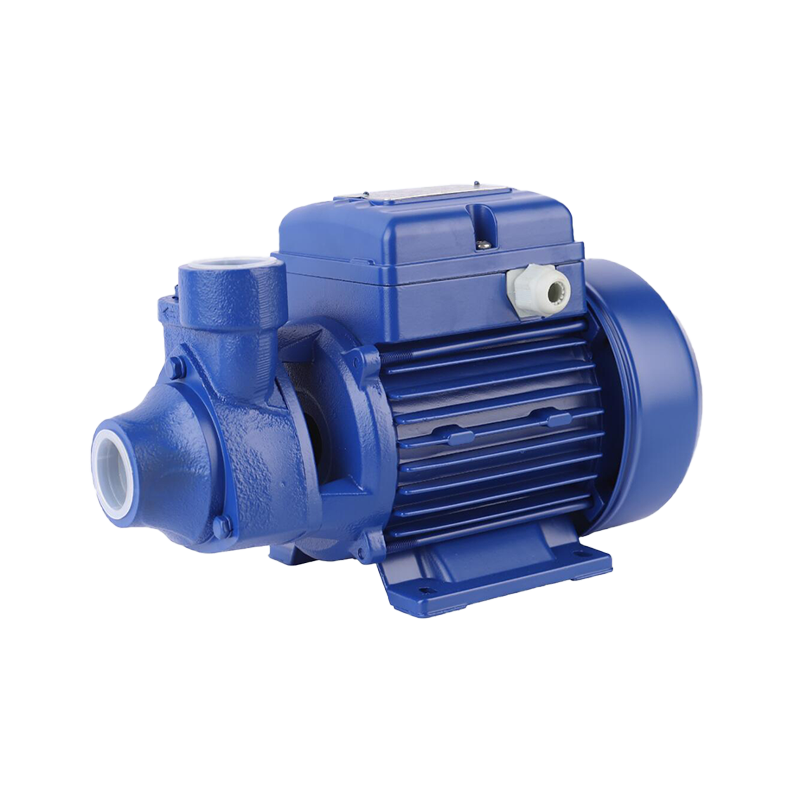

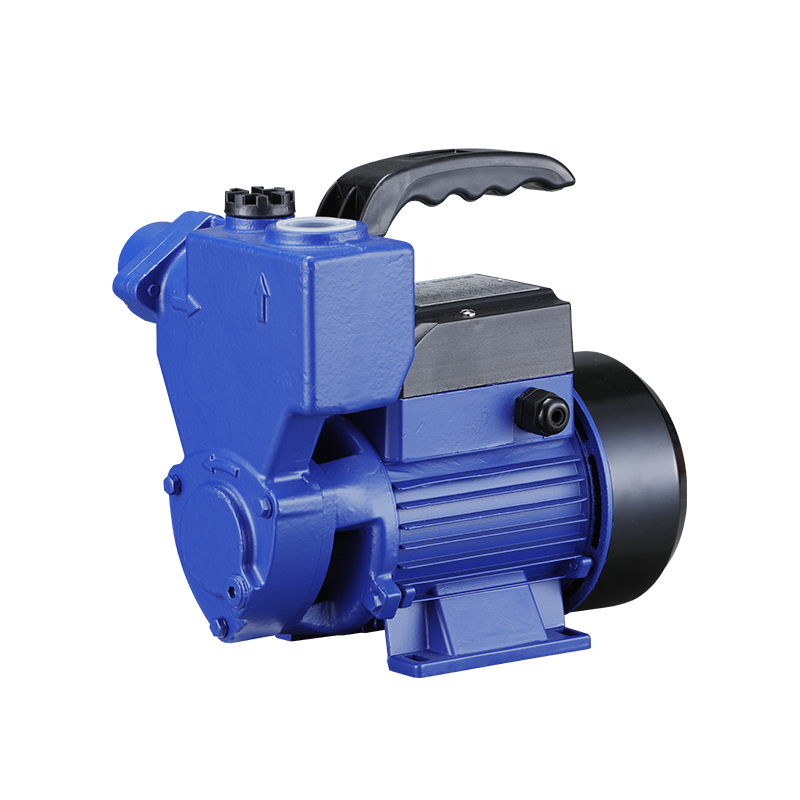

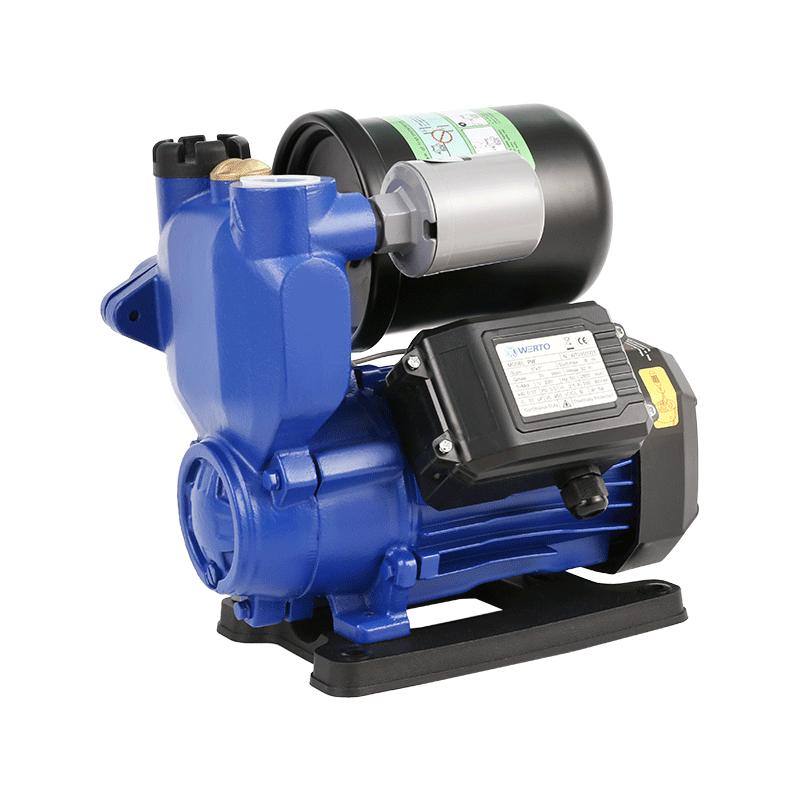

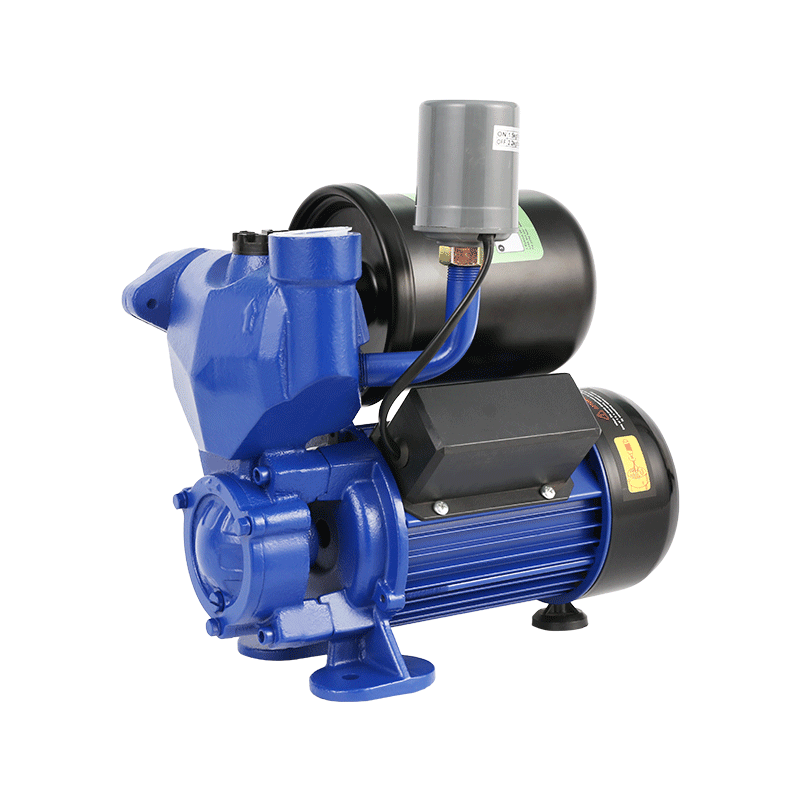

Peripheral water pumps, on the other hand, have a single-stage impeller with a series of radial vanes that rotate within a closed casing, generating pressure and flow by the interaction of the fluid with the impeller. This impeller design allows the pump to handle low flow rates at high pressures. Peripheral water pumps are commonly used for domestic applications such as boosting water pressure in homes or small irrigation systems.

In terms of construction, peripheral water pumps are generally smaller and more compact than centrifugal pumps, and have a simpler construction with fewer components, making them easier to maintain and repair. Centrifugal pumps are typically larger and more complex, with multiple stages and a volute casing that requires precise machining.

Overall, the choice between a centrifugal pump and a peripheral water pump depends on the specific requirements of the application, including flow rate, pressure, head, and efficiency. Centrifugal pumps are better suited for high-flow rate applications at low to medium pressures, while peripheral water pumps are better suited for low-flow rate applications at high pressures.

Introduction to the use of Intelligent Peripheral Pump

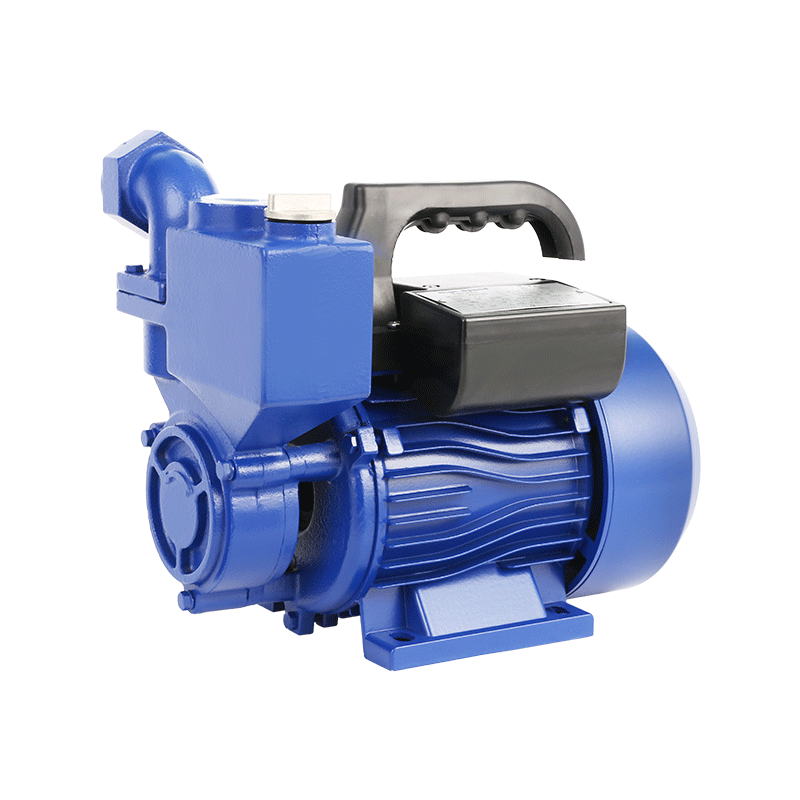

Intelligent peripheral pumps are advanced pumping systems that use smart technology to optimize performance, reduce energy consumption, and improve reliability. These pumps are designed to be highly efficient, reliable, and easy to operate, and are commonly used in domestic, commercial, and industrial applications.

One of the key features of intelligent peripheral pumps is their ability to adjust the speed of the motor to match the required flow rate. This means that the pump can operate at the most efficient speed for the specific application, reducing energy consumption and operating costs. Intelligent peripheral pumps also have advanced control systems that allow them to monitor and adjust various parameters, such as pressure, flow rate, and temperature, to ensure optimal performance.

Another important feature of intelligent peripheral pumps is their ability to communicate with other systems and devices, such as sensors, controllers, and other pumps. This allows for greater control and coordination of the pumping system, reducing the risk of system failure and improving overall efficiency.

Intelligent peripheral pumps can also be equipped with various sensors and monitoring devices, such as vibration sensors, temperature sensors, and pressure sensors, that allow for real-time monitoring of the pump's performance. This information can be used to identify potential problems before they become critical, reducing the risk of downtime and costly repairs.

Overall, intelligent peripheral pumps offer a range of benefits over traditional pumping systems, including improved energy efficiency, greater reliability, and better control and coordination of the pumping system. As a result, they are becoming increasingly popular in various applications, from domestic water supply to large-scale industrial processes.

Where is the intelligence of Intelligent Peripheral Water Pump?

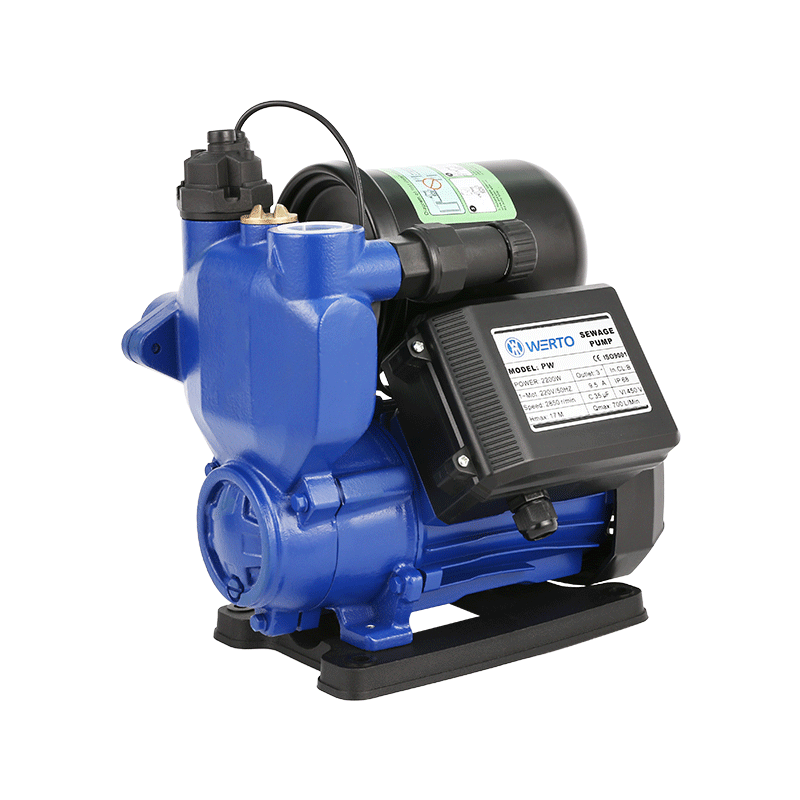

The intelligence of an intelligent peripheral water pump lies in its control system, which is designed to optimize the pump's performance and reduce energy consumption. The control system typically consists of a microprocessor-based controller, sensors, and software algorithms that allow the pump to adjust its speed and other parameters in response to changes in demand.

Intelligent peripheral water pumps are equipped with various sensors, such as pressure sensors, flow sensors, and temperature sensors, that provide real-time feedback on the pump's performance. The controller uses this information to adjust the speed of the motor and other parameters to match the required flow rate and pressure, ensuring optimal performance and energy efficiency.

The control system of an intelligent peripheral water pump can also communicate with other devices and systems, such as sensors, controllers, and other pumps, to coordinate and optimize the operation of the entire pumping system. For example, multiple pumps can be connected in a network and controlled by a central controller, allowing for greater efficiency and reliability.

Intelligent peripheral water pumps can also be equipped with advanced software algorithms that use machine learning and artificial intelligence techniques to optimize performance and reduce energy consumption. These algorithms can analyze data from the sensors and make predictions about future demand, allowing the pump to adjust its operation in anticipation of changing conditions.

Overall, the intelligence of an

intelligent peripheral water pump lies in its advanced control system, which allows the pump to optimize its performance and reduce energy consumption based on real-time feedback and advanced algorithms.

English

English русский

русский عربى

عربى Español

Español